Tempo Zero Premium: APP for manufacturing companies

Tempo Zero Premium for Microsoft Business Central

App tailored for manufacturing companies: it makes them more flexible, more efficient, providing more control tools.

With a range of capabilities and enhancements to the Microsoft Dynamics 365 Business Central standard, Tempo Zero Premium covers the typical features required by Italian companies in the manufacturing.

For a long time, manufacturing processes (which involve the production of large homogeneous quantities of parts) have no longer followed a static plan-execution scheme.

The exception has become the rule: design is constantly evolving, plans are reviewed frequently, subcontractors’ policy is flexible, delivery times are tight and safety margins are minimal.

To meet these needs, NAV-lab has developed the extension Tempo Zero Premium to provide manufacturing companies with flexibility, efficiency and control.

Some additional features are also focused on cost control, traceability and job order production.

Tempo Zero Premium is in addition to the Tempo Zero Cloud extension (its pre-requisite, including the FE Lite Cloud e FE Full Cloud Apps for e-invoicing).

Tempo Zero Cloud + Tempo Zero Premium APPs allow a fast start-up of Microsoft Dynamics 365 Business Central, the ERP for your business management (Saas – Software as a service).

APP Microsoft certified

Available on

Microsoft AppSource marketplace

Pre-requisite:

Tempo Zero Cloud

Tempo Zero Premium: features

Flexibility

It may happen that a product already partially or totally assembled has to be disassembled and then reproduced in a different configuration. It may happen that orders, considered closed, are reopened to be modified. Finally, in the management of subcontracting, it is necessary to precisely define what to send to subcontractors and what to work internally. All these needs are solved by Tempo Zero Premium.

FEATURES

- The disassembly of a produced item (restoration of components in stock and rectification of the finished product).

- The reopening of a production order (change from completed to released state).

- Closing a production order even if some movements or adjustments have been made and the output completely reversed.

- It is possible to indicate which components of a production order are to be sent to the subcontractors and which are to be sent later or not sent at all.

Efficiency

When companies have a very wide range of items and consequently many BOMs (bills of materials), even minimal technical development may require updating many of them. The subdivision of production into many orders of a few pieces means that order closure registration activities can be demanding.

FEATURES

- Possibility of massive replacement of components on the production BOMs to facilitate modification operations (massive insertion of a new article, massive replacement of the existing article with a new article and possible relative quantity, massive elimination).

- Possibility of massive closing of completely finished production orders (for which the output has been completely recorded).

- The generation of production orders from the Planning Worksheet directly in the released state.

Control

For effective monitoring of production progress, raw material and semi-finished product requirements and subcontracting, Tempo Zero Premium offers a dashboard of tools that provide the production manager with an effective overview.

FEATURES

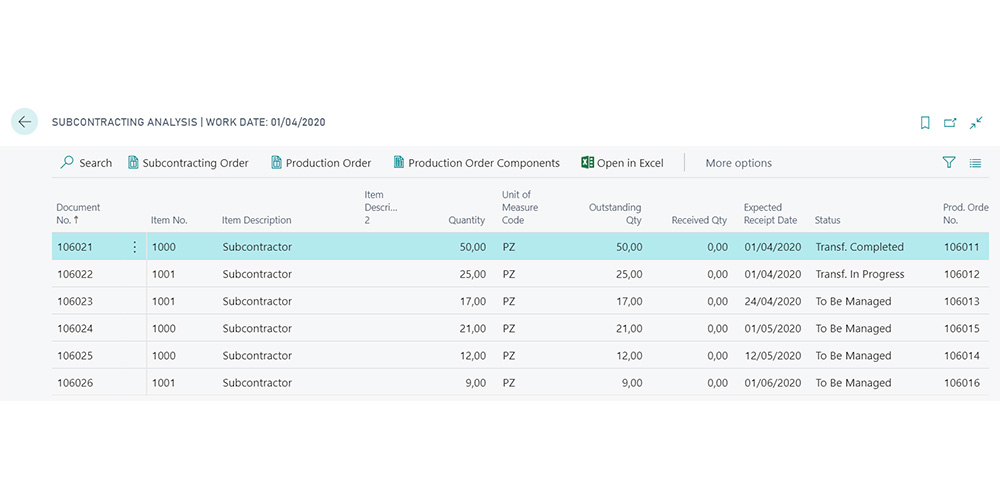

- Statement with analysis of the progress of subcontracting order lines with the identification of the status of transfers to subcontractors.

- Overview of requirements, with indication of expected income and expenses, ordered on the basis of time and accumulated stock at the date. This feature makes it possible to easily plan the company’s requirements, based on expected production and sales.

- Addition of statistical details useful in the production planning phase and on the MRP/MPS prospectus.

- Production Shopfloor: advanced management of production progress (with global overview of the status of production orders and any delays).

- Advanced shipment and reception plans, for the improvement of goods receipt and shipment operations.

- Several improvements to production printing, with the introduction of barcodes for the progress of the stages of production orders.

- Monitoring of Ouput / Consumption for the location: a specific page allows the simultaneous display of all output and consumption movements posted on a location (based on warehouse management). Using filters, it is possible to analyse/verify the status of the various production documents.

Job Orders, Costing and Traceability

- Job order movement report and evaluation (by job order size).

- BOM Valuation at Last Cost: calculation and display with references to cost source documents.

- Analysis of the Production Orders with Costing.

- Traceability on Production Orders: displays and reports showing the movements per production order, including the posting date and batch/serial number, the stock situation detailed per batch with the option to aggregate quantities produced and production times by posting date.

Tempo Zero Premium: screenshots

Replacing components in production BOMs

The BOM component replacement function allows the user to perform a massive advanced management of component replacement

Disassembly

The Disassembly of Production Orders function restores recorded production movements,

returning components to their original warehouses.

Evolution of requirements

With this function the user can analyze how the quantity of a specific article evolves over time,

also considering the expected incoming or outgoing warehouse movements.

Subcontracting analysis

Subcontracting analysis function helps the production manager control the transfer of components to subcontractors

CONTACT NAV-LAB

You will be contacted by our specialists in Microsoft ERP and the Tempo Zero suite of apps. Our consultants are available to provide insights on content, features, usage modes for the benefit of your company, and for a personalized demo.

ACTIVATE THE APP NOW

To activate the app, you need to contact NAV-lab for cost information and support regarding the download and implementation.

It’s also necessary to subscribe to the corresponding online service contract on a monthly or annual basis (SaaS – Software as a Service).

The service cost varies based on the number of users